What is microfiber suede leather ?

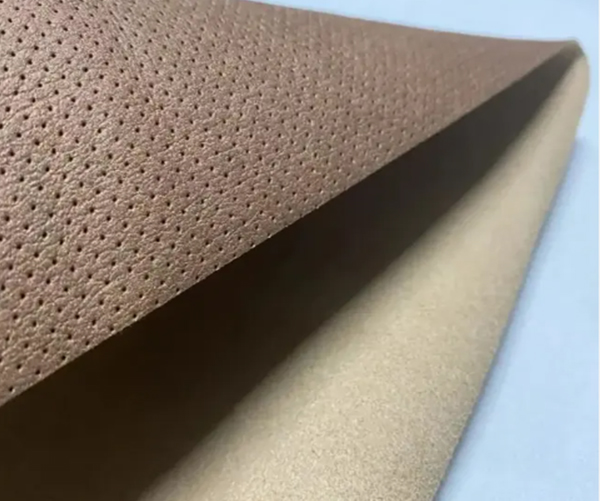

Microfiber suede is simply made of microfiber substrate, and then coated with a layer of PU coating on the surface, which has similar properties to natural leather.

Advantages: Microfiber suede has a good flexing resistance (at room temperature up to 100,000 times without cracks), good tear strength and peel strength , and very eco-friendly (from production to use will not have any pollution, environmental performance is superior)

Disadvantages: Comfort, breathability are a little different from natural leather.

2.The technical principle of microfiber suede

Microfiber suede is made of microfiber with a bundle of collagen fiber structure (fineness 3 ~ 4μm) and similar properties in natural leather. Through the water weaving needling process of the microfiber, a three-dimensional structure of the skin mesh structure is formed,

and then the substrate is soaked through the PVA immersion process. The cloth was impregnated with high weather resistant modified flame retardant PU to form a cortical structure, and then washed away the PV in the water washing process A makes the material have a stable breathable porous structure,

and then through NaOH(or toluene) green process treatment to make the product ultra-fine, and finally through special process treatment such as dyeing, the use of tasteless flame retardant technology, ultra-dermal structure simulation technology, wear resistance, weather resistance treatment to achieve more than natural leather ultra-dermal properties.

3.Microfiber suede process flow

The main process flow is: microfiber → water-woven needling → special composite → stress relief → pre-reduced wire pretreatment → impregnated modified PU(flame retardant)→ kneading and peeling → green ultra-fine treatment → peeling → winding (Besse)→ functional post-treatment → microfiber suede.

The structure of microfiber suede is very similar to that of real leather, both of which are bundles of superfine polyamide fiber three-dimensional structure. The collagen bundles of cowhide are interwoven and tightly woven into the real leather into a network.

The microfiber leather base cloth of microfiber suede is a composite production process of water-woven fabric with three-dimensional structure processing and needle-punched nonwoven fabric with three-dimensional structure, mainly through vertical needling. The vertical and horizontal fibers intertwine to form a network.

Therefore, the appearance and intrinsic physical properties of microfiber suede are more dermal characteristics, and because of the special polyurethane resin with the amino acid structure of cortex, its products truly achieve the characteristics beyond dermal.Microfiber suede is simply made of microfiber substrate,

and then coated with a layer of PU coating on the surface, which has similar properties to natural leather.

Waterproof Oil Embossed Microfiber Film Leather for bags&shoes making popular in South America and the Middle East

Waterproof Oil Embossed Microfiber Film Leather for bags&shoes making popular in South America and the Middle East

Custom safety shoe leather Microfiber vegan leather for shoes upper

Custom safety shoe leather Microfiber vegan leather for shoes upper

Durable Microfiber Shoes Leather Eco-Friendly Microfiber Sneakers Leather

Durable Microfiber Shoes Leather Eco-Friendly Microfiber Sneakers Leather

Microfiber Soft Leather Microfibre Lining Water Absorbent High-Quality Leather

Microfiber Soft Leather Microfibre Lining Water Absorbent High-Quality Leather